Project highlights

Our approach to reducing our carbon impact includes:

- Continuous assessment of our carbon emission baseline, as set out in tenders using our Carbon Interface Tool (CIT) and continued through the construction phase via the scheme specific carbon footprint assessment.

- Training our engineers in the identification of carbon operations, CIT and how to reduce carbon both in design and operational stages.

- Focusing and incentivising our supply chain partners to provide low carbon and where possible, carbon neutral products and services.

Throughout all our operations Linxon is fully committed to minimise its carbon footprint to help support the electricity industry and our wider supply chain to deliver net zero carbon construction projects. We aim to halve CO2 emissions by 2030 and reach net-zero by 2050.

We continually look for equipment and material supply options and methods of working which will significantly reduce both embodied and operational carbon by collaborating with our Client and challenging all our team, including our supply chain partners, during both the design and delivery stages of our projects.

Carbon reduction starts already at tender stage

The plan for carbon management starts at tender stage by reviewing the works and identifying areas within the design and procurement options where we could reduce carbon utilising low and zero carbon options from lessons learnt on previous and current projects.

An example is the potential to use a screw pile solution which could significantly reduce the amount of concrete used and associated aggregates thus reducing the carbon footprint on sites.

Our engineers complete a qualitative and quantitative assessment of the carbon options and use this data during the design decision making and design process.

Linxon will collaborate with our Clients to mutually agree from the start our carbon reduction plans and agree whether support is available for challenging decision making that could reduce carbon including supporting technical challenges where carbon reductions are possible but technical barriers currently exist.

Our engineers can then finalise the designs in accordance with the above decision making, ensuring that carbon specific elements of designs are included in the construction.

We understand that the best way to support our Clients in achieving net zero carbon during the construction phase is through focused design, material use, installation and commissioning techniques to avoid carbon intensive activities at all stages of our projects and through our supply chain.

We have identified the following proposals which we foresee will provide the greatest impact in support of a net zero target:

- Reducing SF6 usage across the grid network

- Reducing embodied carbon within substation equipment

- Reducing embodied carbon during construction

- Reducing energy consumption on site

Linxon also propose utilising electric vehicles, including charging stations, on project sites to further reduce carbon emissions.

Innovation to drive sustainability

Linxon considers a number of innovative options to drive value on its projects. Innovations, when applied, will aim to improve health and safety, reduce the carbon footprint, minimise waste, support local environmental issues, increase biodiversity or add to social value across the construction phase of the project.

The sustainable innovations below are some examples of the type of design initiatives Linxon can provide.

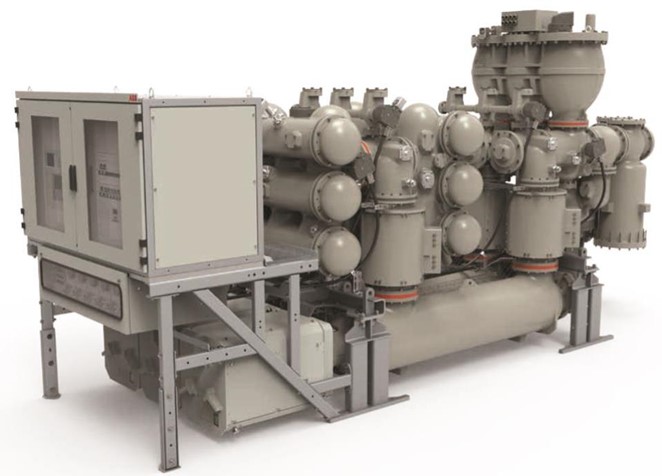

- With our equipment provider Hitachi Energy, we can offer a new compact Gas Insulated Switchgear (GIS), that has a 33% decrease in equipment size/weight and a subsequent 30% reduction in GIS building size which is primarily made up of carbon intense materials (steel and concrete).

- The Hitachi Energy portfolio also offers an Eco GIS/GIB for projects which reduces almost 100 percent of the global warming potential, compared with SF6.

- Consider screw piling – reduce concrete – carbon reduction which could significantly reduce the amount of concrete use and associated aggregates thus reducing the carbon footprint on sites.

- We power our LV security lighting using solar power. In order to conserve energy we also use energy efficient lighting (LED).

- Battery installation to replace diesel generator option.

- Recycled plastics for geotech membrane and drainage pipework.

Sustainability is at the heart of everything we do – from Linxon’s purpose and company values, to the projects we work on, to the way we design and deliver our work.