Linxon uses Building Information Modelling (BIM) as part of its digital ecosystem to enhance its customer experience, do more with less and underline the company’s drive to further leverage digital-based services. Read more on the benefits of BIM for all kinds of substation projects.

“BIM helps us improve our data – both what we collect and how we use it,” says Jose Restrepo, Global Head of Engineering at Linxon. “We can make a comparison with a paper map vs Google Maps. Thirty years ago, when we went on a trip, we would buy a physical map and follow the route – but it didn’t tell us about road works or traffic conditions, or about hotels and restaurants on the way. Now, we go on Google Maps and have this real-time information at our fingertips. It’s all about having better access to fully connected, richer data.”

More specifically, BIM involves the generation and management of digital representations of any kind of infrastructure, capturing not only the physical dimensions but other attributes such as catalogue parts, materials, the manufacturing process and origins, and the testing process.

Mohammed Tageldin Younes, Head of Engineering for Linxon in the UK , continues: “Taking a transformer as an example, the data made available include its designs, interfaces, ratings, materials, components, the factory it came from, the manuals associated with it and the tests it has undergone. This enables us to facilitate reliable and robust data availability – required for the operation and maintenance and further allowing the operators to add data related to any maintenance, repairs, or even failures, to the BIM database. This helps maintain the integrity of the designs and information necessary throughout the complete lifecycle of the assets, avoiding loss of data at handover points between the different lifecycle stages”

BIM isn’t just deployed within the energy industry, but across a number of areas including aerospace, construction, architecture and major infrastructure projects to plan, design, construct, operate and maintain the assets involved in such industries.

“While BIM can monitor the status of an asset, it has many other uses,” Jose adds. “A digital representation of the reality, is for example used for clash detection of components before they are physically installed on a project. We can also incorporate changes in one specific area that then propagate automatically throughout the whole project design. And by connecting all the parties involved in constructing a particular physical space, we can ensure that everyone is working in a harmonized environment with less room for errors in the interface.”

So, what are other concrete benefits of BIM?

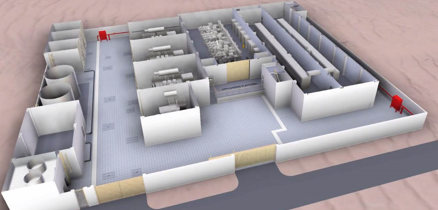

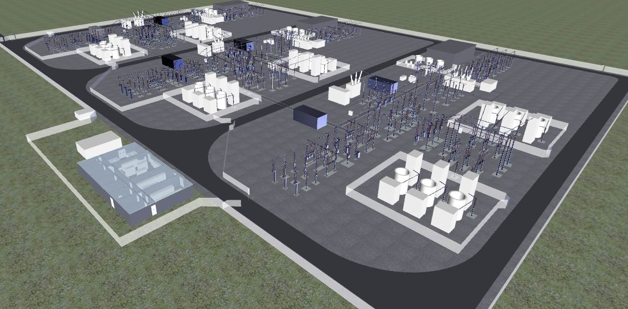

One of the main benefits in terms of stakeholder engagement is simply allowing a client to picture what the design will look like in real life ahead of project execution. “An engineer who’s deeply embedded in their project can already ‘see’ the substation before it’s constructed,” Jose explains. “But not everyone on the project will have this technical background. BIM enables everyone to visualize the final design – and this, in turn, helps us to outline the features, explain the intentions and, ultimately, gain confidence and buy-in.”

Having a clear picture from the start is key to managing the overall project costs and schedule, as well as speeding up decision-making and improving predictability. “You can see if there will be any errors or clashes at an early stage and avoid those,” he continues.

“Let me give you an example. If we need to change the type of HVAC, we can tweak the design, let those changes propagate immediately in the virtual environment and we could then identify right away if the new HVAC fits or whether another fixture needs to be relocated, for instance.” This is important considering how expensive modifications are on site – in particular in remote locations like offshore windfarms. The final result: more aggressive schedules can be maintained, alongside better, efficient planning of manpower and timescales.

BIM also improves real-time collaboration. Several different designers for a substation project can work together from geographically distributed locations on the same cloud-stored virtual representation. “Each designer can focus on their own piece – like the building, the trenches or the foundations – and see how their changes affect someone else’s piece straight away,” Jose adds.

Virtual models of the substation

Does this light the path to a fully digital future?

“There’s no simple answer as to exactly what the digital future will look like, but BIM is certainly one of a host of digital-based services we offer our customers. Others include remote factory acceptance tests, virtual site visits and information management solutions. At Linxon, we use a certain level of digitalization on every project, customized to the client needs and the project itself,” Mohammed explains. “In terms of trends, BIM reinforces the thinking that digitalization helps you do more with fewer resources and that there’s greater value in having as much information if you keep it easily accessible and highly structured.”

Looking at the future, BIM anticipates the full virtualization of reality. What will the impact of this be on substation projects? Before anyone steps on site, a detailed representation will already be available and this will be constantly updated during construction. Mohammed continues: “If we need to verify a distance between two points or equipment now, someone still has to travel to the site and take a measurement. In the future, we’ll be able to remotely deploy a drone to take that measurement, which will input this into our database and allow the engineer to be able to check the installation straight away.”

BIM also reflects the growing shift towards the centralization of the different eco-systems of information, assets, tools and people. Reflecting Linxon’s collaborative approach, not only are all our teams fully digitally connected across the globe, but external experts are integrated into the company’s network to expand our wealth of knowledge, where required. As Jose sums up, “Our core business is power engineering, so we’re bringing in external specialists in virtual reality, LiDAR scanning and AI, for example, to ensure that we can both deliver our core capabilities while treading a steady path into the digital future.”